Spining

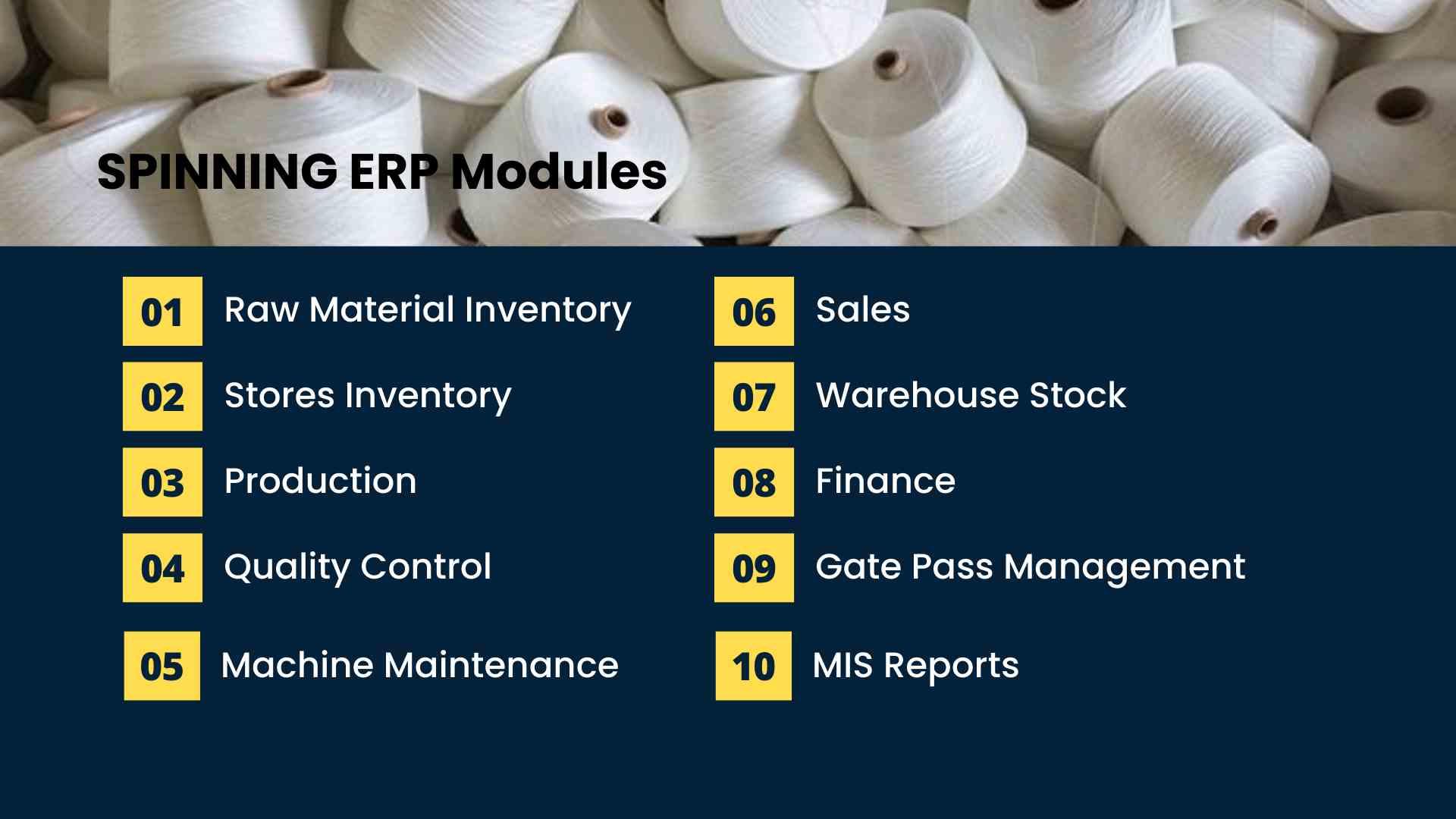

Being a powerful tool, Winsoft Solutions ERP helps in managing the entire range of spinning mill operations at an ease by integrating all the departments of a spinning mill seamlessly. The Spinning ERP for spinning industry helps people in controlling all the operations and activities of a spinning mill right from Fibre procurement to yarn production. This can be accessed via a gateway or an innovative dashboard from anywhere across the world in the most effective, accurate, and efficient way. This ERP for spinning industry will be designed for a multi-user environment for ensuring the complete process of the company with no need for physical and manual flow of documents.

Fiber Management

Effectively manage your fiber procurement, inventory, and consumption with our Fiber Management module in ERP. This module streamlines fiber-related processes, ensuring accurate tracking and optimization of fiber usage. Manage raw material purchasing, including supplier management and price tracking. Track fiber stock levels, including storage locations and quantity.

Yarn Production

Production Planning- Plan and schedule yarn production based on demand and capacity. Allocate raw materials (fibers) to production orders. Track spinning processes, including machine allocation and production monitoring. Manage winding processes, including yarn packaging and labeling. Track twisting processes, including yarn finishing and treatment. Monitor yarn quality parameters, such as strength, fineness, and color. Track production progress, including machine efficiency and operator performance.

Order Management

Manage customer orders, including sales orders and returns and Automate order processing, including credit checking and inventory allocation. Allocate inventory to orders, including backorder management. Manage shipping processes, including carrier selection and freight calculation. Automate invoicing, including payment terms and discount management. Track order status, including shipping and delivery updates. Generate insights on order management performance, including order fulfillment rates and shipping costs.

Production Planning

Production Scheduling Create and manage the job orders and work orders. Allocate resources, such as machines, labor, and tools, to production tasks. Calculate material requirements based on production schedules and inventory levels. Plan and manage production capacity, including machine and labor utilization. Track production progress, including work-in-progress (WIP) and finished goods. Generate insights on production performance, including efficiency, productivity, and quality.

FutherMain Features

To try the most advanced business

Raw Material Inventory

The Raw material Inventory Module of provides the details of Raw Material purchases. It helps to enquire and raise an order for fiber particulars like Cotton, Polyester, and Viscose. It also helps to test and approve the sample and Bulk Fibers. It provides an additional option to make purchases without inquiry (direct purchase). It helps to know the Bale weight differences between the Mill and the Supplier. It helps to show Invoice and return details

- RM Sample Enquiry

- RM Sample Receipt

- RM Sample Testing

- RM Sample Approval

- RM Material Purchase Order

Stores Inventory

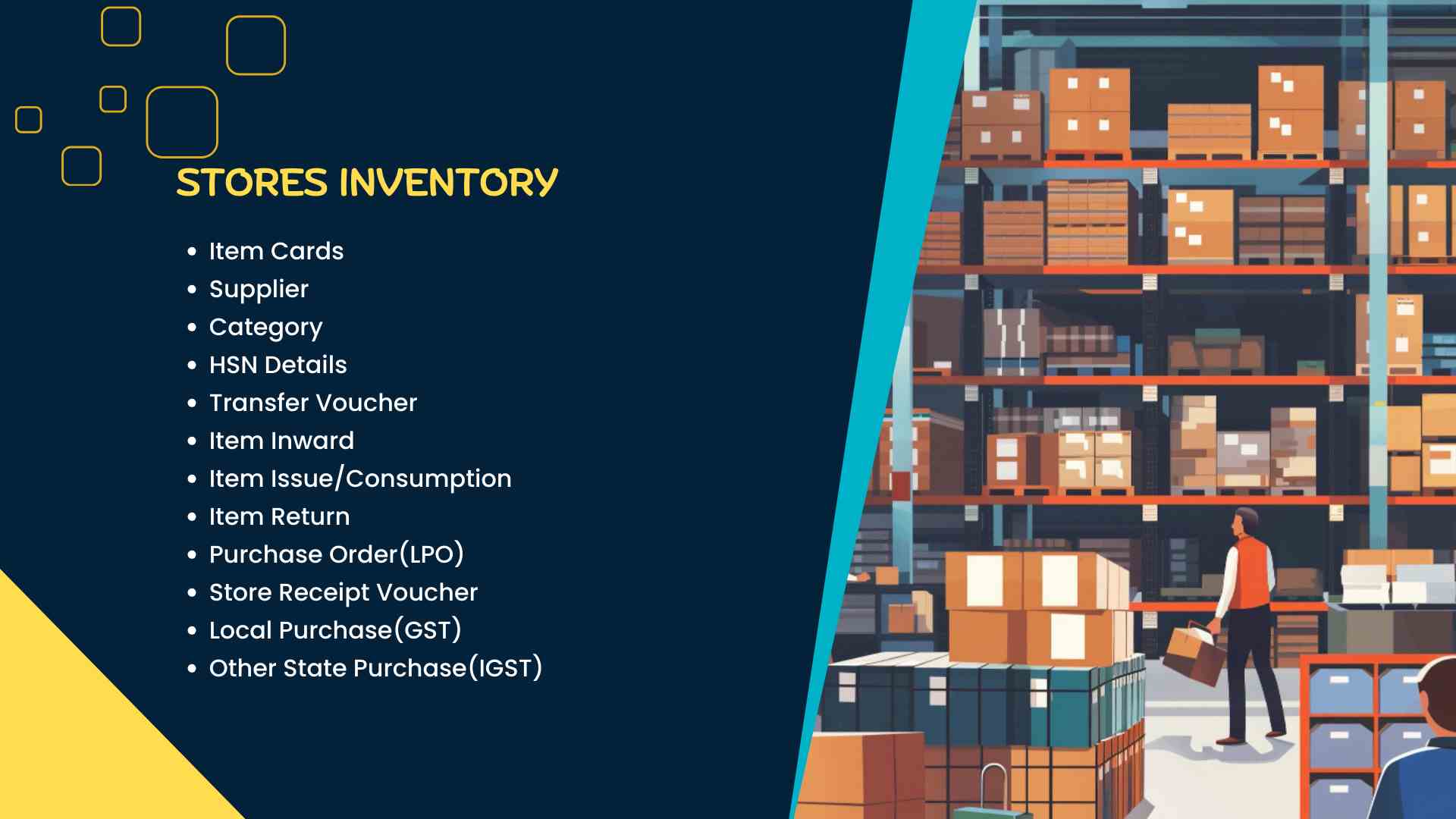

The Spinning Stores Inventory Module of WS SPINNING ERP allows generating and maintaining the store's material with all types of UOM. Material requirements can be generated as a purchase indent and it can be allotted and approved by the admin with the quantity and price alteration, based on the allotment, a quotation will be received and the ERP system generates the quotation comparison so that the user can identify the best one in the aspect of Pricing and Delivery schedule.

- Item Inward

- Item Issue/Consumption

- Item Return

- Purchase Order(LPO)

- Store Receipt Voucher

- Local Purchase(GST)

- Other State Purchase(IGST)

Production

The Spinning Production Module of WS SPINNING ERP provides the overall Production details of the Spinning Unit. It also helps to view the Preparatory, carding, comber, finisher draw frame, and speed frame details which include machine details, count, Target Production/Shift, Stoppage details, Efficiency, and Utilization. It's also used to keep the details of Spinning, Winding, and packing details.

- Carding

- Pre Comber Drawing

- Comber

- Finisher Draw Frame

- Speed Frame

- Spinning

Quality Control

Spinning mills producing cotton or blended yarns need to evaluate several properties to ensure the quality of slivers, roving's and yarns.

- Standard Master Drawing

- Standard Value Fixation

- Quality Control

- Reports

Machine Maintenance

The Spinning Machine Maintenance Module of WS SPINNING ERP provides the Machines Maintenance Details, Preventive Maintenance Schedule, and Breakdown details. A preventive maintenance schedule leads to an increase the Production.

- Machine Registration

- Service Movement

- Service Entry

- Reports

Sales

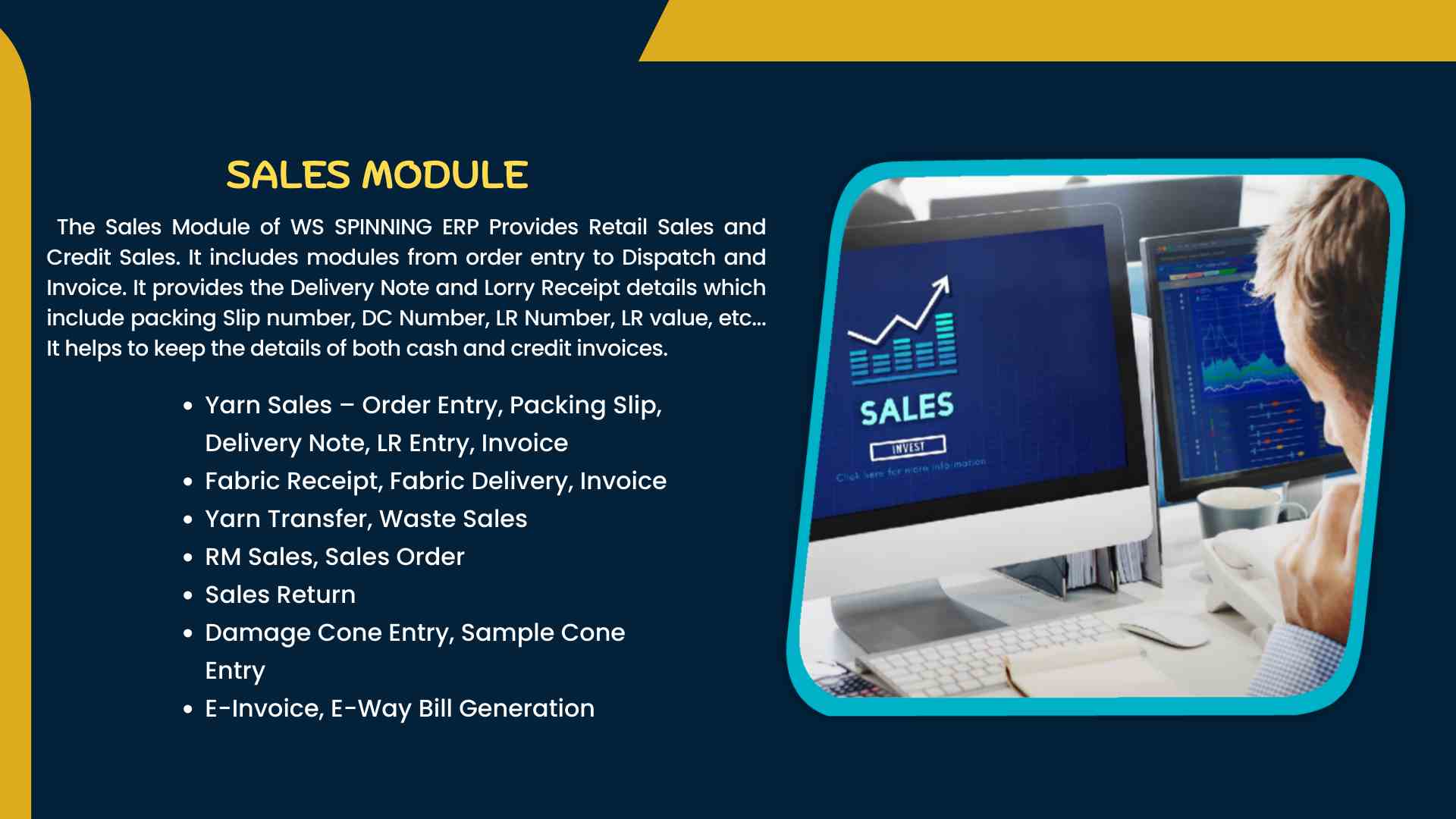

The Sales Module of WS SPINNING ERP Provides Retail Sales and Credit Sales. It includes modules from order entry to Dispatch and Invoice. It provides the Delivery Note and Lorry Receipt details which include packing Slip number, DC Number, LR Number, LR value, etc... It helps to keep the details of both cash and credit invoices.

- Yarn Sales

- Fabric Receipt

- RM Sales

- Sales Order

- Sales Return

Warehouse Stock

The Warehouse Stock Module of WS SPINNING ERP provides the stock details for stores and Raw material such as cotton, polyester and etc…It also helps to maintain the stock details for Yarn in terms of cones and Bags.

- Multiple Warehouse

- Stores Delivery

- Stores Department Return Receipt

- Stores Direct Stock Entry

- Stores Stock Adjustment

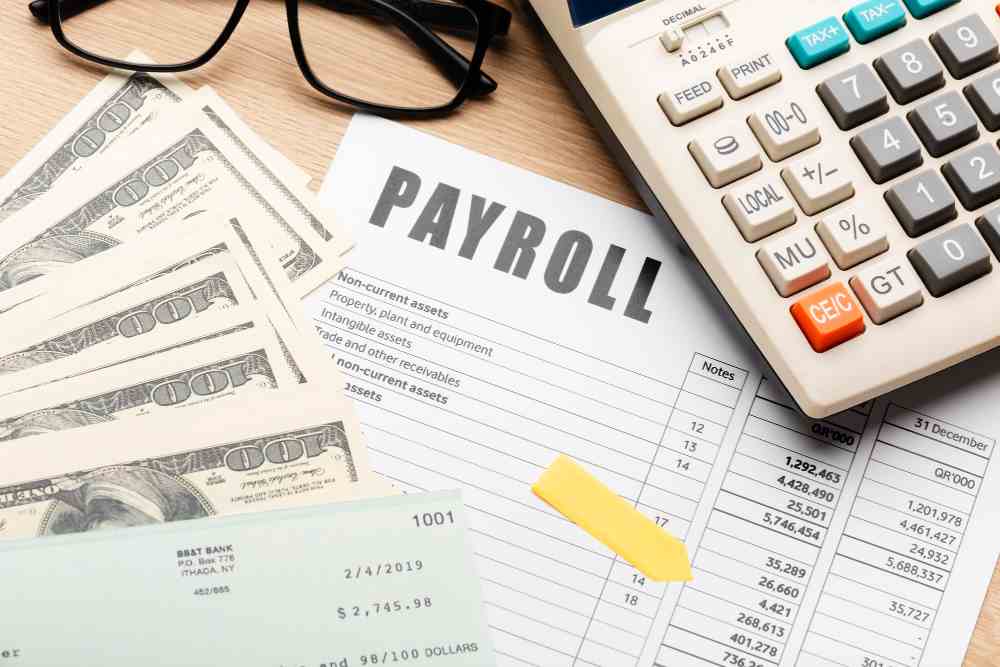

Finance

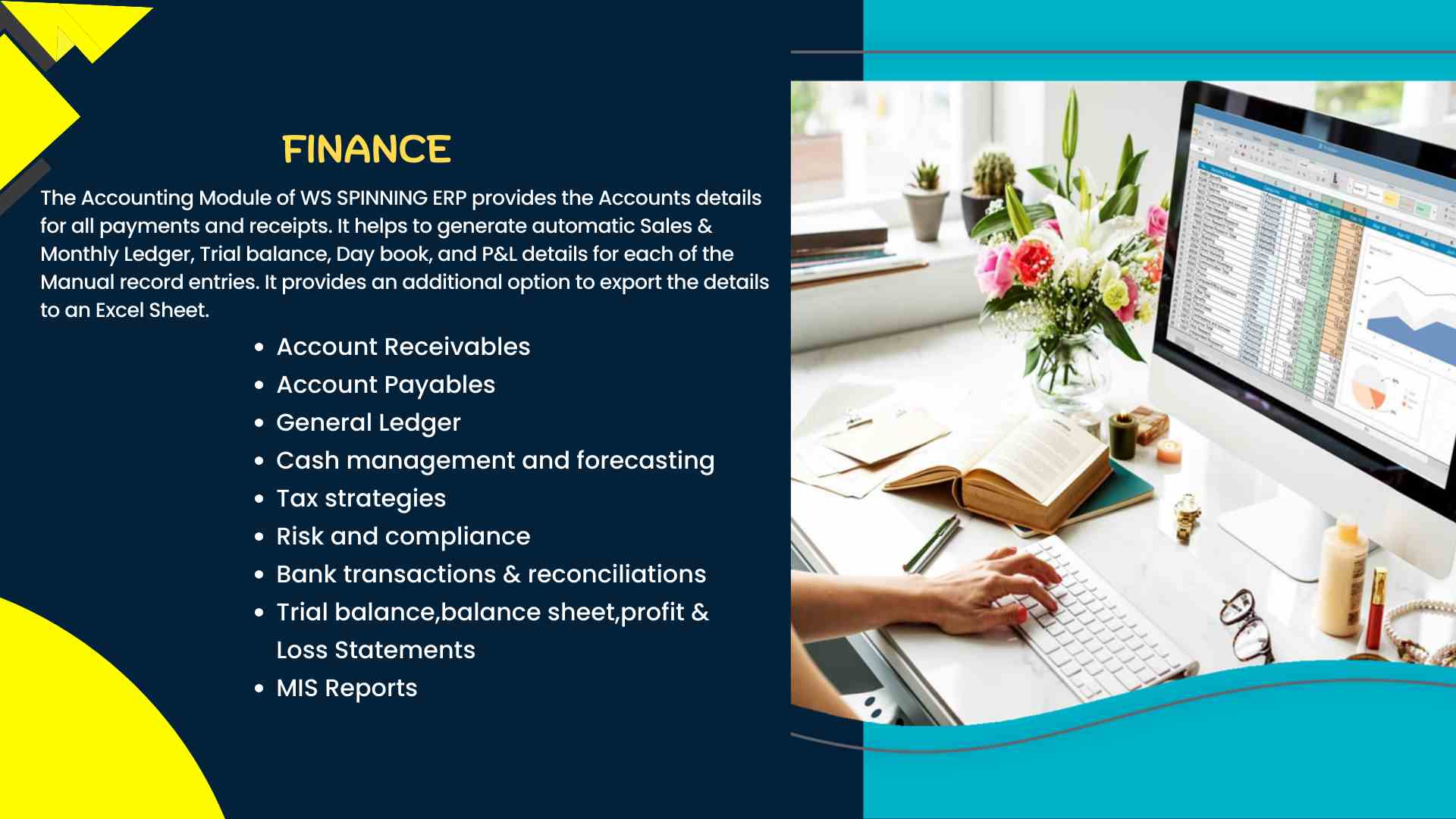

The Accounting Module of WS SPINNING ERP provides the Accounts details for all payments and receipts. It helps to generate automatic Sales & Monthly Ledger, Trial balance, Day book, and P&L details for each of the Manual record entries. It provides an additional option to export the details to an Excel Sheet.

- Account Receivables

- Account Payables

- General Ledger

- Cash management and forecasting

- Tax strategies

- Risk and compliance

- Bank transactions & reconciliations

- Trial balance,balance sheet,profit & Loss Statements

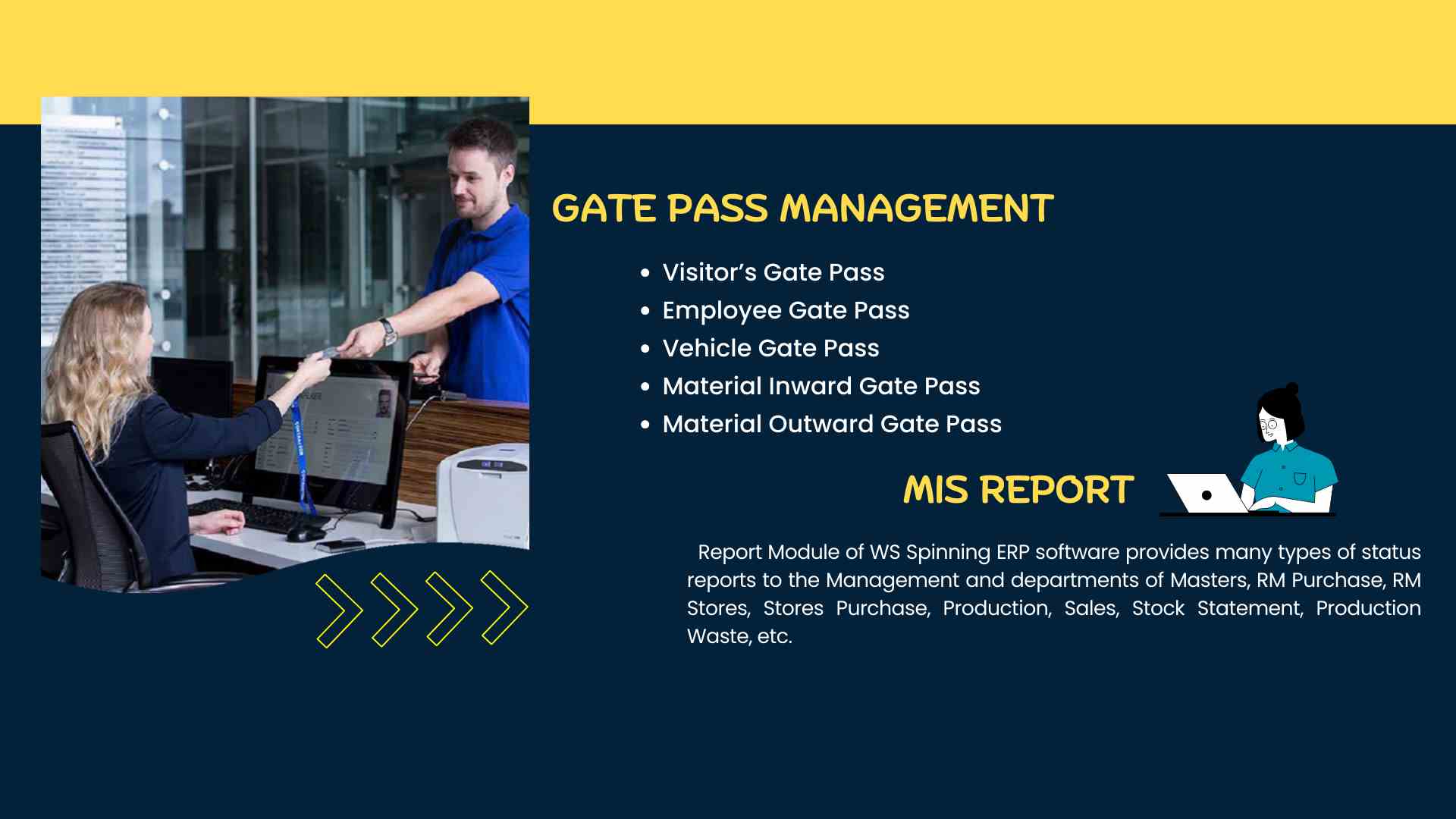

Gate Pass Management

This module automates the process of issuing, tracking, and managing gate passes for visitors, employees, contractors, and vehicles.

- Visitor’s Gate Pass

- Employee Gate Pass

- Vehicle Gate Pass

- Material Inward Gate Pass

- Material Outward Gate Pass

MIS Reports

Report Module of WS Spinning ERP software provides many types of status reports to the Management and departments of Masters, RM Purchase, RM Stores, Stores Purchase, Production, Sales, Stock Statement, Production Waste, etc.

Our Great Team

Sankar

Founder

Mohamed

Marketing

Divya

Designer

Sekar

Development Lead

Deepthi

HR Management

Vinoth

Sales HeadBuild Team Success

Our team of experts is dedicated to delivering innovative IT solutions that drive business success. With years of experience in software development, project management, and technical expertise, our team members are passionate about leveraging technology to solve real-world problems.

Support System

Our leaders inspire and motivate

Our developers create and innovate

Our project managers guide and support

Our quality assurance specialists ensure perfection

Our support specialists care and serve

Over 30.000 Customers

and let's see what are they saying

Lorem ipsum dolor sit amet consectetuer adipiscing elit euismod tincidunt ut laoreet dolore magna aliquam dolor sit amet consectetuer elit

Mark Nilson

DirectorLorem ipsum dolor sit amet consectetuer adipiscing elit euismod tincidunt aliquam dolor sit amet consectetuer elit

Lisa Wong

ArtistLorem ipsum dolor sit amet consectetuer elit euismod tincidunt aliquam dolor sit amet elit

Nick Dalton

DeveloperFusce mattis vestibulum felis, vel semper mi interdum quis. Vestibulum ligula turpis, aliquam a molestie quis, gravida eu libero.

Alex Janmaat

Co-FounderVestibulum sodales imperdiet euismod.

Jeffrey Veen

DesignerPraesent sed sollicitudin mauris. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Inna Rose

GoogleSed ornare enim ligula, id imperdiet urna laoreet eu. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Jacob Nelson

SupportAdipiscing elit euismod tincidunt ut laoreet dolore magna aliquam dolor sit amet consectetuer elit

John Doe

MarketingNam euismod fringilla turpis vitae tincidunt, adipiscing elit euismod tincidunt aliquam dolor sit amet consectetuer elit

Michael Stawson

Graphic DesignerQuisque eget mi non enim efficitur fermentum id at purus.

Liam Nelsson

ActorInteger et ante dictum, hendrerit metus eget, ornare massa.

Madison Klarsson

DirectorVestibulum sodales imperdiet euismod.

Ava Veen

WriterUt sit amet nisl nec dui lobortis gravida ut et neque. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Sophia Williams

AppleNam non vulputate orci. Duis sed mi nec ligula tristique semper vitae pretium nisi. Pellentesque nec enim vel magna pulvinar vulputate.

Melissa Korn

ReporterProduct Portfolio

Our Work

Production & Quality

Our production services are designed to help manufacturers and producers optimize their production processes, improve product quality, and increase efficiency. We offer a range of services. We work with clients to create production schedules, allocate resources, and set production goals. Production Optimization We analyze production workflows, identify bottlenecks, and implement improvements to increase efficiency and reduce waste. Quality control measures to ensure products meet industry standards and customer expectations. We implement lean manufacturing principles to reduce waste, improve quality, and increase customer satisfaction. Our production services are tailored to meet the unique needs of each client, and our team of experts has experience working in a variety of industries, including consumer electronics, automotive, food processing, and aerospace.

Read More

Our Plan

To try the most advanced business

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

Book A Demo

Contact Form

Kindly describe your request in details, and provide us your phone number to contact you back.