Factory Management

The manufacturing industry is highly dynamic and competitive in nature which makes it imperative for such businesses to have an integrated solution that can enhance efficiency, diminish costs, increase sales and profitability but most importantly, enable the organization to make accurate, informed, and strategic decisions. An enterprise resource planning system such as ERP for manufacturing industry might be the answer to all these requirements.

ERP for manufacturing industry integrates all aspects of business (resources, operations, monitoring, reporting, sales, accounting, and finance, etc.) and empowers businesses to function smoothly by maintaining a single database.

Streamlined operations

ERP modules can automate and streamline business processes, which can improve productivity and daily operations. Automating routine tasks and workflows frees up staff to focus on higher-value activities. Streamlined processes reduce manual errors, minimize delays, and optimize resource allocation.

Enhanced quality control

ERP modules can help manufacturers maintain high-quality standards. Schedule and manage quality inspections, reducing manual errors. Analyze quality data to identify trends, patterns, and areas for improvement.

Better supply chain visibility

ERP modules can help manufacturers improve the efficiency of their supply chains, which can lead to on-time deliveries and lower production costs. Track materials, products, and orders across the entire supply chain. Identify and mitigate potential disruptions, such as delays or shortages.

Strategic Decision Making

A comprehensive ERP solution for manufacturing improves the decision-making ability of an organization. It provides thorough insights and visibility into every department and business process helping the company to make informed, spot-on, and faster business decisions.

Improved Compliance and Risk Management

ERP systems help manufacturing companies comply with industry regulations and standards by providing built-in reporting and monitoring tools. These systems can track and document compliance with regulatory requirements, reducing the risk of non-compliance penalties. Additionally, ERP solutions provide robust risk management features, enabling organizations to identify, assess, and mitigate potential risks effectively.

FutherMain Features

To try the most advanced business

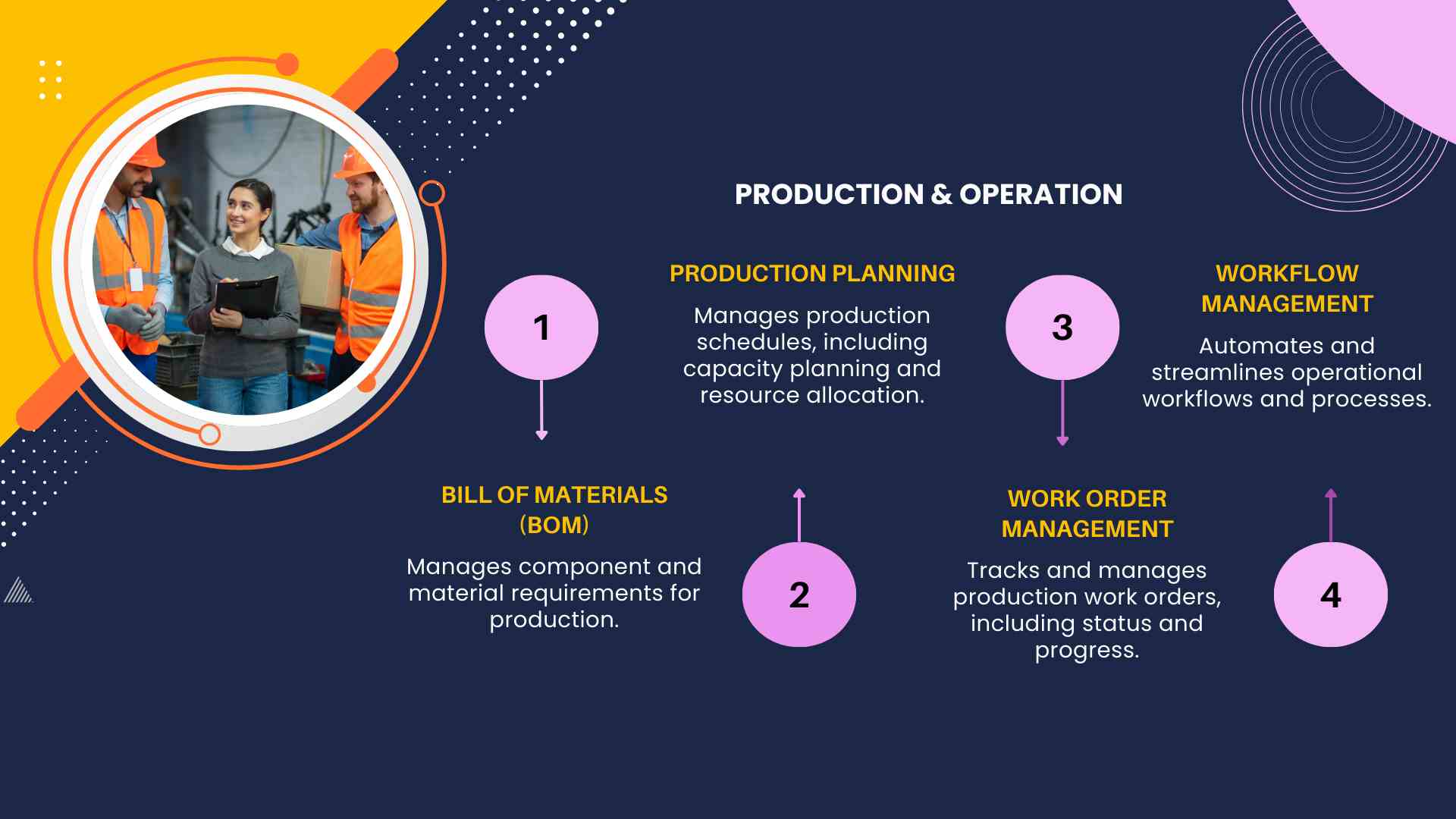

Production and Operation

Smart Factory Integration: Integration with smart factory technologies for real-time monitoring and control. Predictive Maintenance: AI-driven predictive maintenance for reduced downtime and increased efficiency. Real-time Production Tracking: Real-time tracking of production processes for improved visibility and control. Digital Work Instructions: Digital work instructions for improved operator efficiency and reduced errors.

- Bill of Materials(BOM)

- Production Planning

- WorkOrder Management

- WorkFlow Management

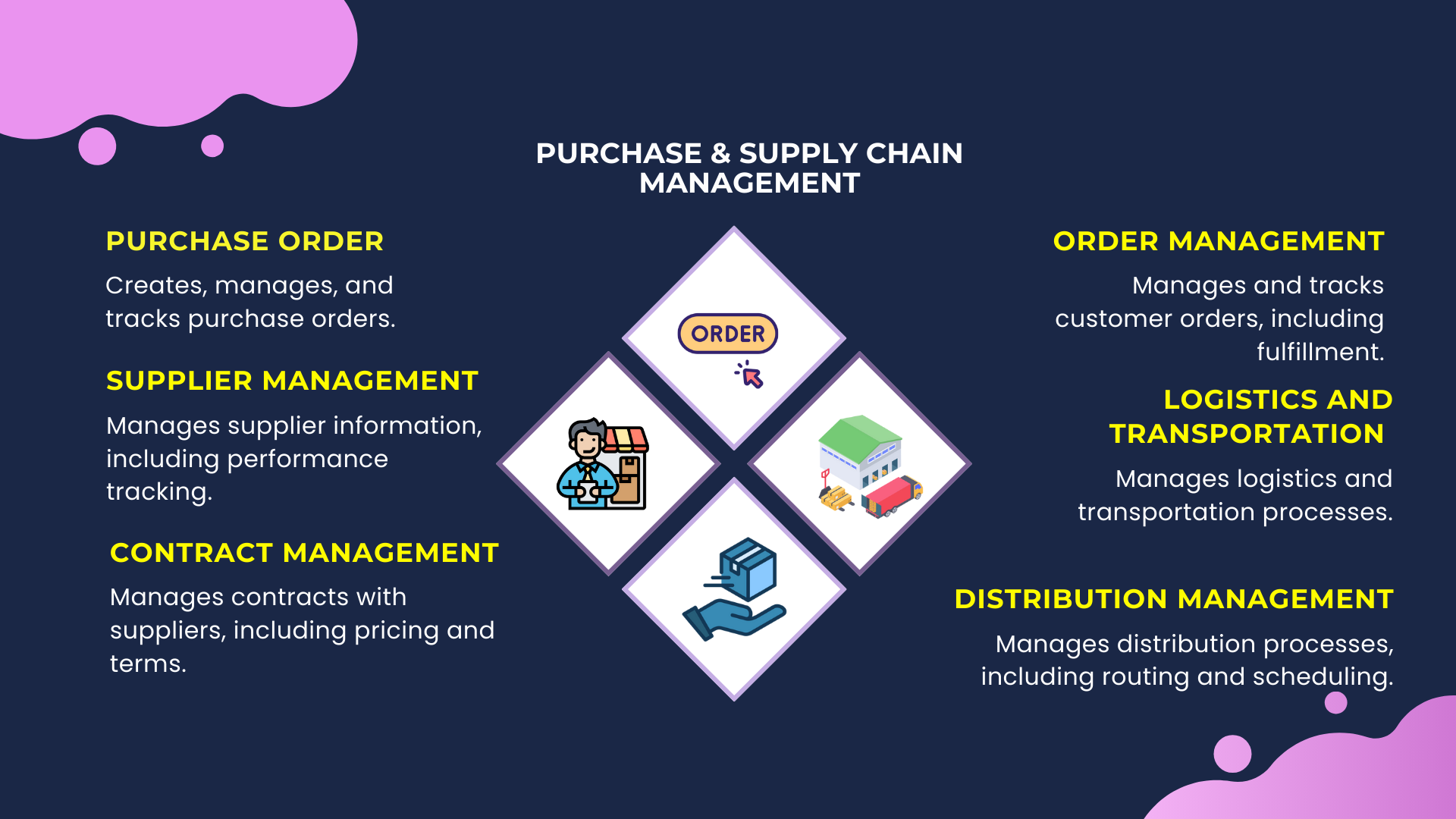

Purchase & Supply Chain Management

Supply Chain Visibility: Real-time visibility into supply chain operations for improved tracking and management. Supplier Relationship Management: Integrated supplier relationship management for improved collaboration and performance. Collaborative planning and forecasting with suppliers and partners.

- Purchase Order

- Supplier Management

- Contract Management

- Order Management

- Logistics and Transportation

- Distribution Management

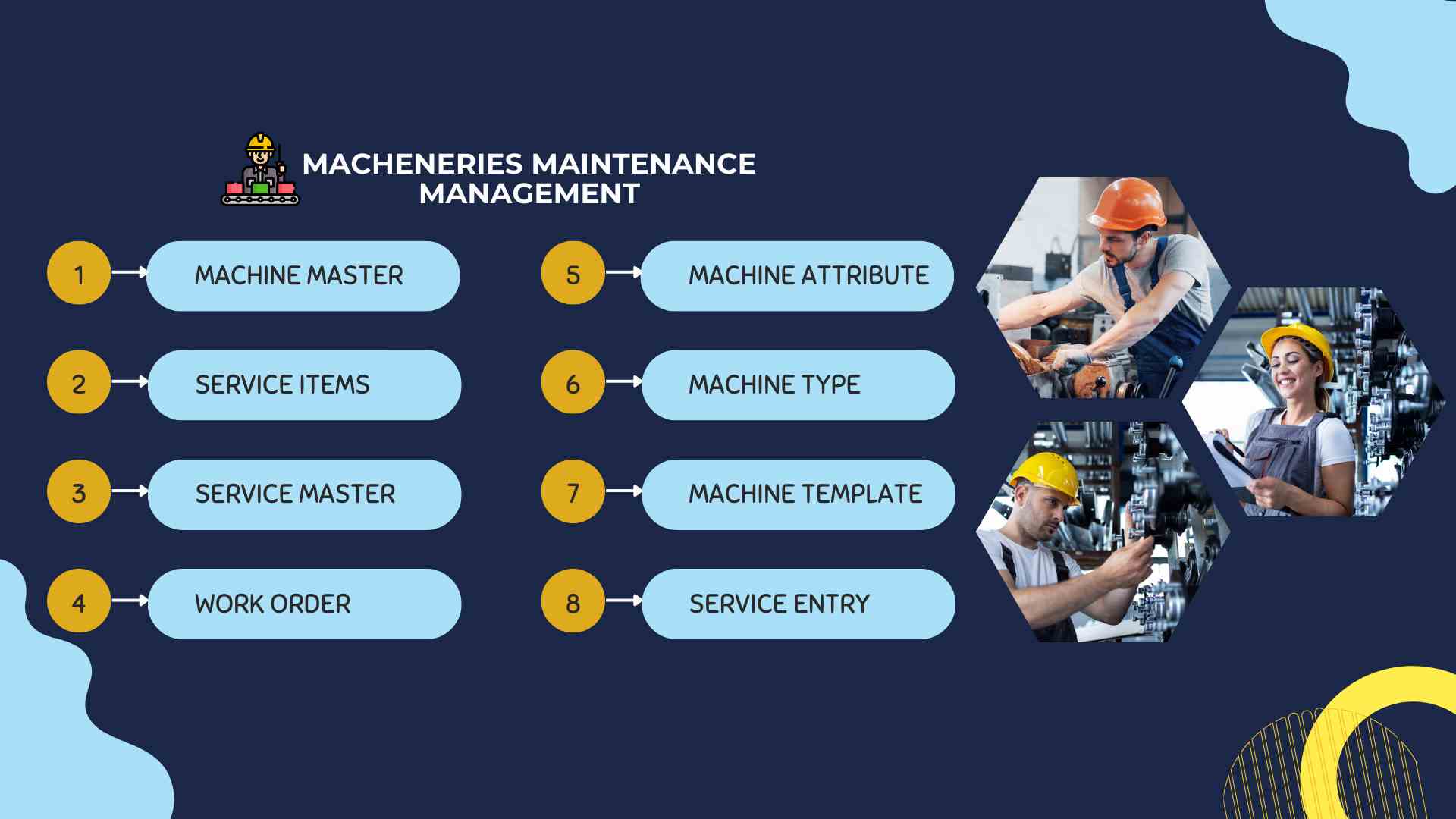

Macheneries Maintenance

Scheduling Plans and maintenance tasks in advance.Create, assign, and track maintenance work orders.Monitor and record machinery usage, performance, and maintenance history.Track machinery condition in real-time, enabling predictive maintenance.Automate routine maintenance tasks, reducing unplanned downtime.Streamline repair processes, minimizing equipment downtime.Manage spare parts and materials, ensuring timely availability.

- Machine Master & Machine Attribute

- Service Items & Machine Type

- Service Master & Machine Template

- Work Order & Service Entry

warehouse management

Receive and inspect incoming goods, verify against purchase orders and update inventory records.Unload goods from trucks, containers, or ships, and move them to designated storage areas.Store goods in designated areas, ensuring proper labeling, stacking, and organization.Track and manage inventory levels, including stock rotation, counting, and reconciliation.Pick and gather items from storage to fulfill customer orders or production needs.Pack and prepare items for shipping, including labeling, wrapping, and loading.

- Multiple Warehousing

- Location Management

- Picking and Packing

- Shipping and Receiving

- Inventory control

- Barcode Scanning

Material Management

Determine material requirements based on production schedules, forecasts, and inventory levels.Purchase materials, negotiate prices, and manage suppliers.Receive and inspect materials, verify quality and quantity.Store materials, track inventory levels, and optimize storage space.Release materials to production or other departments as needed.

Monitor and adjust inventory levels, manage stockroom operations.Dispose of excess, obsolete, or scrap materials.

- Material Master

- Material Forecasting

- Material Substitution

- Material Requirements

- Planning (MRP)

- Material Tracking

Quality Control

The Visually examine products or materials for defects or irregularities.Conduct tests to ensure products meet specifications, standards, and regulations.Take precise measurements to verify product dimensions, weight, etc.

Select random samples for testing to represent the entire production batch.Identify and classify defects or non-conformities.Determine the underlying causes of defects or issues.Implement changes to processes or procedures to prevent future defects.Confirm that corrective actions have been effective.Maintain accurate records of quality control activities, results, and certifications.

- Measurement

- Testing

- Documentation

- Defect Identification

- Verification

- Corrective Action

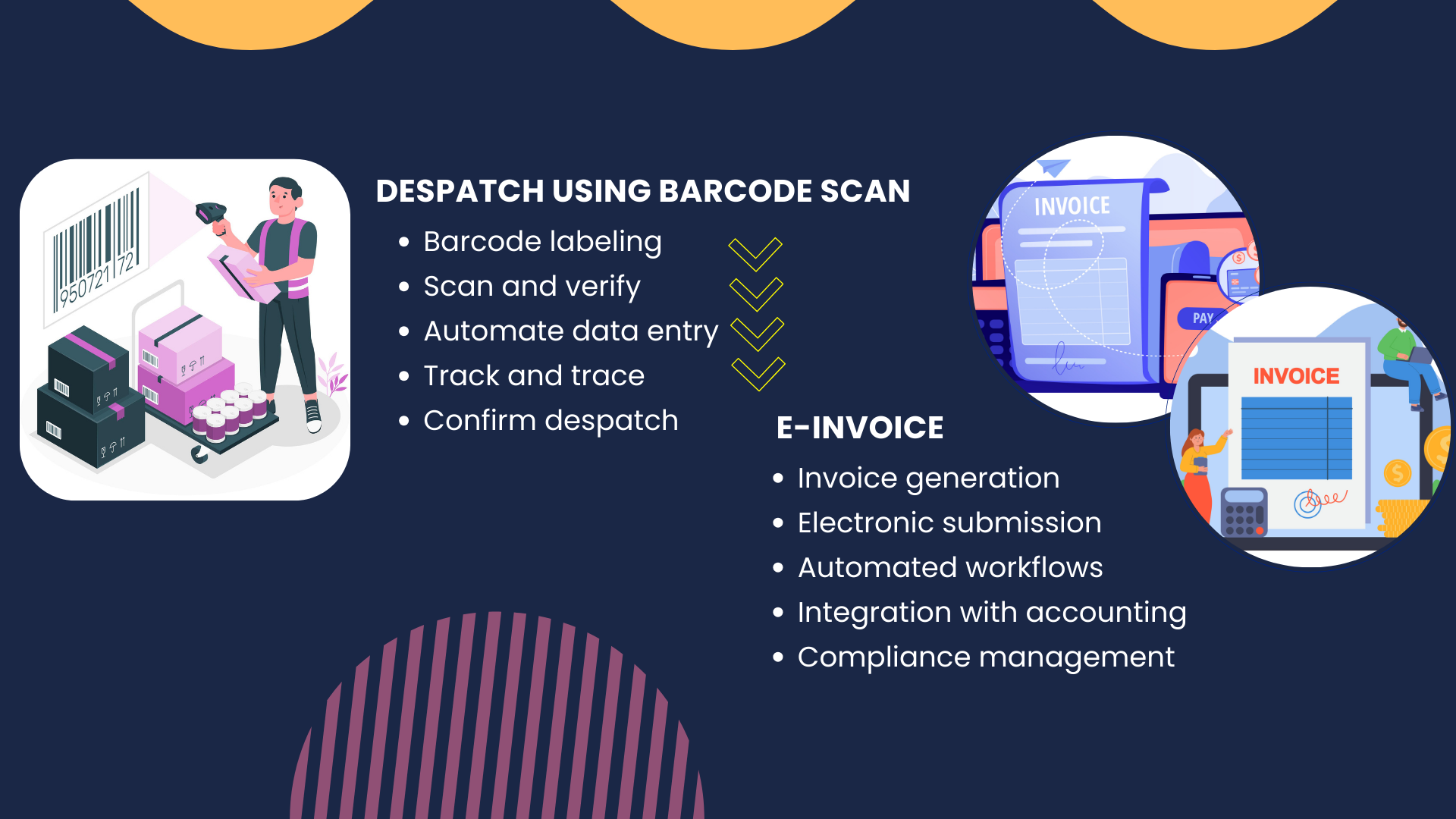

Despatch using barcode scan

Pick items from inventory and pack them into shipping containers.Scan the barcode on each item to verify it matches the order.Scan the barcode on the shipping label to confirm the correct address.Verify order details, such as quantity, product, and shipping address.Automatically update inventory levels as items are scanned.Generate shipping documents, such as packing slips and invoices.Scan the barcode on the shipping container to track packages.

Verify the contents of the container match the order.Seal the container and apply shipping labels.Scan the container barcode to track the shipment.

- Barcode labeling

- Scan and verify

- Automate data entry

- Track and trace

- Confirm Despatch

E-Invoice

E-Invoices are processed faster, reducing payment delays.Electronic invoices minimize errors, ensuring accurate data.

E-Invoices save paper, printing, and postage costs.Electronic invoices enable easy tracking and monitoring.

E-Invoices are more secure, reducing the risk of fraud and tampering.It help meet regulatory requirements, such as tax laws and audits.Deploy the e-invoicing system, transitioning from paper-based invoices.Continuously monitor and evaluate the e-invoicing process, addressing any issues.

- Invoice Generation

- Electronic submission

- Automated workflows

- Integration with accounting

- Compliance Management

Mobile app

Monitor production progress, track work orders, and receive real-time updates.Scan barcodes to track inventory levels, receive alerts for low stock, and optimize storage.Conduct quality inspections, report defects, and assign corrective actions.Schedule maintenance, track equipment performance, and receive alerts for issues.Track employee attendance, monitor work hours, and assign tasks.Generate reports, analyze data, and make data-driven decisions.Automate tasks, reduce paperwork, and enhance productivity.Collaborate with teams, share information, and ensure everyone is on the same page.Reduce costs, optimize resources, and improve overall factory performance.

Data Security And Backup

Limit access to authorized personnel, use secure login credentials, and implement role-based access.Encrypt sensitive data, both in transit and at rest, using robust encryption algorithms.Install firewalls and antivirus software to prevent unauthorized access and malware attacks.Conduct regular security audits to identify vulnerabilities and address them.

Use secure protocols for data transfer, such as SFTP or HTTPS.Perform regular backups of critical data, ideally daily or weekly.Store backups offsite, in a secure location, to prevent data loss in case of a disaster.Consider cloud backup solutions for added security and scalability.

Our Great Team

Sankar

Founder

Mohamed

Marketing

Divya

Designer

Sekar

Development Lead

Deepthi

HR Management

Vinoth

Sales HeadBuild Team Success

Our team of experts is dedicated to delivering innovative IT solutions that drive business success. With years of experience in software development, project management, and technical expertise, our team members are passionate about leveraging technology to solve real-world problems.

Support System

Our leaders inspire and motivate

Our developers create and innovate

Our project managers guide and support

Our quality assurance specialists ensure perfection

Our support specialists care and serve

Over 30.000 Customers

and let's see what are they saying

Lorem ipsum dolor sit amet consectetuer adipiscing elit euismod tincidunt ut laoreet dolore magna aliquam dolor sit amet consectetuer elit

Mark Nilson

DirectorLorem ipsum dolor sit amet consectetuer adipiscing elit euismod tincidunt aliquam dolor sit amet consectetuer elit

Lisa Wong

ArtistLorem ipsum dolor sit amet consectetuer elit euismod tincidunt aliquam dolor sit amet elit

Nick Dalton

DeveloperFusce mattis vestibulum felis, vel semper mi interdum quis. Vestibulum ligula turpis, aliquam a molestie quis, gravida eu libero.

Alex Janmaat

Co-FounderVestibulum sodales imperdiet euismod.

Jeffrey Veen

DesignerPraesent sed sollicitudin mauris. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Inna Rose

GoogleSed ornare enim ligula, id imperdiet urna laoreet eu. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Jacob Nelson

SupportAdipiscing elit euismod tincidunt ut laoreet dolore magna aliquam dolor sit amet consectetuer elit

John Doe

MarketingNam euismod fringilla turpis vitae tincidunt, adipiscing elit euismod tincidunt aliquam dolor sit amet consectetuer elit

Michael Stawson

Graphic DesignerQuisque eget mi non enim efficitur fermentum id at purus.

Liam Nelsson

ActorInteger et ante dictum, hendrerit metus eget, ornare massa.

Madison Klarsson

DirectorVestibulum sodales imperdiet euismod.

Ava Veen

WriterUt sit amet nisl nec dui lobortis gravida ut et neque. Praesent eu metus laoreet, sodales orci nec, rutrum dui.

Sophia Williams

AppleNam non vulputate orci. Duis sed mi nec ligula tristique semper vitae pretium nisi. Pellentesque nec enim vel magna pulvinar vulputate.

Melissa Korn

ReporterProduct Portfolio

Our Work

Planning and Scheduling

Analyze historical data and market trends to determine forecasted demand. Calculate material requirements, determine inventory levels, and identify procurement needs. Analyze production capacity, identify capacity constraints, and determine capacity requirements. Create production schedule, allocate resources, and sequence production orders. Create work orders, assign tasks, and track progress. Manage inventory levels, track inventory movements, and optimize inventory. Coordinate with suppliers, manage logistics, and track shipments. Analyze schedule performance, identify bottlenecks, and optimize schedule. Track production progress, identify deviations, and take corrective action. Analyze performance metrics, identify areas for improvement, and implement changes.

Read More

Our Plan

To try the most advanced business

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

- System Storage Auditing

- Customized Reports

- Unlimited Training

- Data Migration and Developer Support

- 24X7 Online Support

- Direct Customer Visit for Customer Support

- Regular and Weekly Back up

Book A Demo

Contact Form

Kindly describe your request in details, and provide us your phone number to contact you back.